The modern automotive industry's shift towards high-strength steel emphasizes the critical need for updated frame repair safety standards. Recent guidelines focus on precision, environmental impact, and worker safety through robotic welding, advanced measurement tools, and comprehensive training. Auto collision centers must adapt by investing in modern equipment and ensuring strict adherence to these standards to maintain structural integrity, enhance vehicle safety, and streamline frame repair processes.

The latest updates to frame repair safety standards, focusing on high-strength steel, signify a significant leap forward in workshop security. With the increasing prevalence of advanced automotive materials, understanding and adhering to these updated protocols is paramount for professionals in the auto body repair industry. This article delves into the critical importance of safety standards, explores key changes in high-strength steel frame repair, and provides guidance on implementing new measures for enhanced workshop protection.

- Understanding the Importance of Safety Standards in Frame Repair

- Key Changes and Upgrades in High-Strength Steel Frame Repair Protocols

- Implementing and Adhering to New Safety Measures for Enhanced Workshop Security

Understanding the Importance of Safety Standards in Frame Repair

The significance of safety standards in frame repair cannot be overstated, especially with the advent of high-strength steel in automotive manufacturing. As vehicles become increasingly robust and complex, ensuring proper repair techniques is paramount to prevent compromising structural integrity. Frame repair safety standards serve as a cornerstone for maintaining the safety and performance of vehicles post-damage and repair.

Adhering to updated guidelines ensures that auto body work and auto frame repair are conducted meticulously, aligning with the latest advancements in material science. This involves understanding how high-strength steel behaves under stress, choosing the right tools and techniques, and adhering to best practices. Such standards safeguard against potential hazards associated with car damage repair while guaranteeing that vehicles return to their pre-incident condition or even surpass it in terms of structural soundness.

Key Changes and Upgrades in High-Strength Steel Frame Repair Protocols

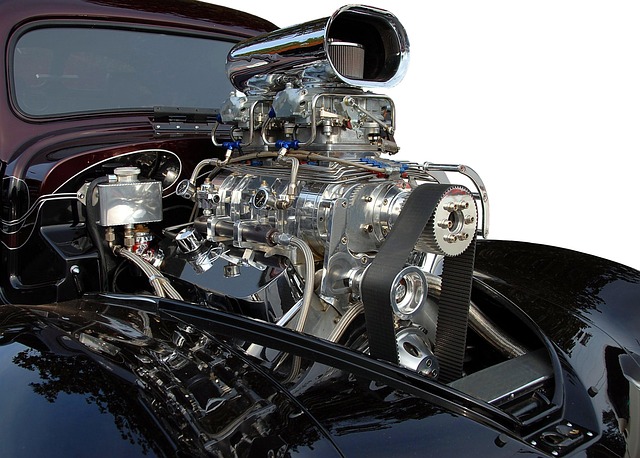

The recent updates to frame repair safety standards for high-strength steel have brought about several key changes and upgrades in protocols, reflecting advancements in vehicle manufacturing and crash testing technologies. One of the most notable shifts is the increased emphasis on precision and specialized tools required for effective high-strength steel frame repairs. This includes a wider adoption of robotic welding systems and advanced measurement devices to ensure structural integrity and minimize post-repair discrepancies.

Additionally, these updates have clarified guidelines for handling and processing high-strength steels, focusing on environmental considerations and worker safety. The new standards also emphasize the importance of training and certification programs for collision centers and vehicle body repair shops, ensuring that technicians are equipped with the knowledge and skills to handle these advanced materials properly. This shift towards stricter adherence to frame repair safety standards is not just about enhancing vehicle safety during collisions but also streamlining fender repair processes, ultimately leading to more efficient and effective vehicle body repairs.

Implementing and Adhering to New Safety Measures for Enhanced Workshop Security

As frame repair techniques continue to evolve with advancements in high-strength steel, so too must the safety standards within auto collision centers and workshops. The updated frame repair safety measures prioritize enhanced workshop security, ensuring a safer environment for workers and reducing the risk of accidents. These new protocols include rigorous training programs for staff on handling high-strength steel, proper use of personal protective equipment (PPE), and adherence to strict guideline during fender repair or auto body painting processes.

Workshops are now encouraged to implement state-of-the-art equipment designed specifically for high-strength steel frame repairs, such as advanced welding systems and precision measuring tools. Adhering to these new safety measures not only fosters a culture of accountability but also ensures compliance with the latest industry standards. This commitment to safety is paramount, especially in bustling auto collision centers where the combination of powerful machinery and skilled labor demands constant vigilance.

The updated frame repair safety standards for high-strength steel reflect a commitment to enhancing workshop security and ensuring the well-being of professionals working with these advanced materials. By implementing the key changes outlined in this article, automotive shops can maintain compliance, improve safety protocols, and protect their workforce from potential risks associated with high-strength steel frames. These upgrades are a step towards a safer and more secure future for frame repair, benefiting both employees and customers alike.