TL;DR:

Frame repair safety standards are essential for precise, safe vehicle restoration after accidents. These guidelines equip auto body technicians with protocols for realigning car frames using specialized equipment and techniques. Adherence ensures structural integrity, prevents complications, and enhances the quality and longevity of repairs. While challenging to implement, especially in cost-sensitive environments, prioritizing these standards fosters worker safety and boosts customer trust in automotive repair services.

In the realm of construction and building maintenance, ensuring structural integrity during frame repair is paramount. This article delves into the critical aspect of frame repair safety standards and their application in structural realignment. We provide a comprehensive overview of these standards, explore best practices for implementation, and discuss key considerations to navigate potential challenges. By understanding and adhering to these safety guidelines, professionals can effectively restore structural stability while prioritizing worker and site safety.

- Understanding Frame Repair Safety Standards: A Comprehensive Overview

- Implementing Structural Realignment: Best Practices and Precautions

- Ensuring Safety Compliance During Frame Repair: Key Considerations and Challenges

Understanding Frame Repair Safety Standards: A Comprehensive Overview

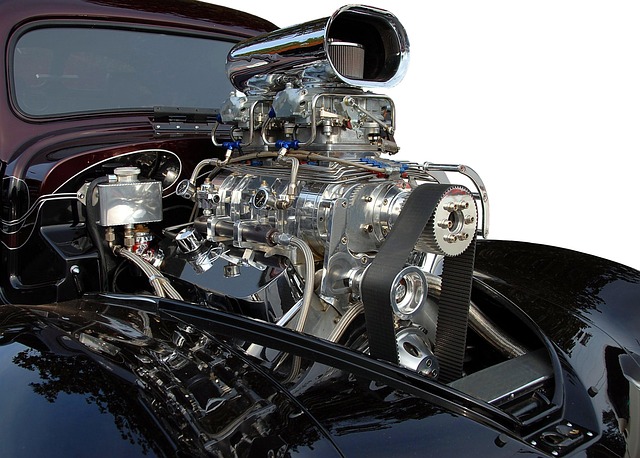

The frame repair safety standards are a crucial aspect of ensuring structural integrity and safety in vehicle restoration and alignment processes. These standards guide auto body technicians and repair shops through the intricate task of realigning car frames after accidents or damage, such as those resulting from car collisions. Comprehending these guidelines is essential for achieving precise and secure repairs, preventing further complications, and ensuring the vehicle’s structural stability.

When it comes to frame repair, especially in the context of auto dent repair and auto body work, adherence to safety standards plays a vital role. These standards outline specific procedures for assessing frame damage, using specialized equipment for realigning components, and applying the correct techniques to restore the car’s structure without compromising its safety. By following these protocols, technicians can effectively mitigate risks associated with accidents, ensuring that the vehicle is not only cosmetically repaired but also structurally sound, ready for the road again.

Implementing Structural Realignment: Best Practices and Precautions

Implementing Structural Realignment involves meticulous planning and adherence to frame repair safety standards. It’s a complex process that requires professionals in vehicle bodywork to carefully assess and modify the vehicle’s structural framework. Best practices dictate the use of advanced equipment and techniques, ensuring precise adjustments while minimizing damage. Precautions include wearing appropriate personal protective equipment (PPE) and using specialized tools designed for accuracy and safety.

Automotive repair shops specializing in frame repairs follow these guidelines to maintain integrity throughout the realignment process. By adhering to industry standards, they guarantee that the vehicle’s structural integrity is restored without compromising safety. This meticulous approach not only ensures a solid foundation for future repairs but also enhances the overall performance and longevity of the vehicle body shop’s services, reflecting their commitment to high-quality automotive repair.

Ensuring Safety Compliance During Frame Repair: Key Considerations and Challenges

Ensuring safety compliance during frame repair is paramount when undertaking structural realignment. Frame repair safety standards are designed to protect both workers and vehicles from potential hazards. These standards encompass a range of key considerations, including proper training for technicians, use of specialized equipment, and adherence to strict protocols for handling and disposing of hazardous materials. For instance, in the case of auto dent repair or vehicle dent repair, ensuring structural integrity while minimizing exposure to toxic substances is crucial.

Challenges in meeting these standards often arise from the dynamic nature of auto collision repair processes. Repair shops must remain agile and adaptable, continually updating their practices to align with evolving industry safety guidelines. Additionally, managing costs while adhering to safety protocols can be a delicate balance, especially for smaller workshops. However, prioritizing safety not only ensures the well-being of workers but also promotes high-quality repairs, fostering customer trust in the long run, similar to how auto collision repair professionals maintain vehicle aesthetics.

The implementation of robust frame repair safety standards is paramount in ensuring structural integrity during realignment processes. By adhering to comprehensive guidelines, professionals can mitigate risks effectively. Understanding these standards, best practices, and potential challenges enables seamless structural adjustments while prioritizing safety, ultimately leading to more secure and compliant buildings.